Vitreous Enamel – A new perspective on old technology

Written by Anthony “Ajay” Bean – Graphic Artist

Vitreous Enamel as a technology has been around for centuries. Enamel coatings have been used ever since the times of ancient Egypt, where artisans would use the process of using heat to bake on colour coatings to coat jewelry, stone and pottery with durable sealed glazes to protect these items from damage. It was indeed quite an expensive process back then, saved only for the Pharaohs and Kings of the time. There has also been evidence that the ancient Celts, Georgians, and Chinese, used this particular technology to coat metals with protective coatings to prevent them from tarnishing and rusting.

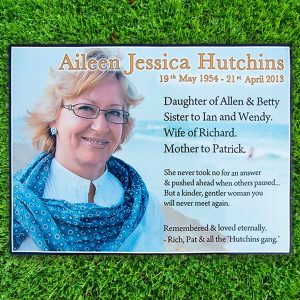

An enamelled coating, not to be confused with an enamel paint (or an oil-based paint), is a coating which is consistent of powdered glass which is heated to its melting point and fused to the substrate (or core material), to form a vitreous (smooth) coating. At Forever Shining, we use Vitreous enamel coatings to preserve images on to plaques in order to protect them from the rigours of UV Light, rock and stone chips, bore water and scratches. This article explains in depth, the vitreous enamel printing process we use here at Forever Shining, in order to provide a better quality product for preserving images, and the many, many ways which you can use a Vitreous Enamel Plaque.

Why Vitreous Enamel?

Well, there are several reasons why you would be better to choose Vitreous Enamel imaging over rivalling products such as Dye Sublimated Aluminium (Offered by most cemeteries for use on plaques) and Ceramic imaging (a more traditional way of preserving images). For one, unlike the two competing products, Vitreous Enamel must always be applied to a hard metal product with a high melting point due to the nature of the coating process. This means by default, your image and/or plaque will be more durable than any aluminium or ceramic image. The additional benefit of Enamelling is that the colour is permanently baked on to the product, forming a hard skin that protects the metal underneath, protecting said metal from corrosion from water or airborne sources.

We combine the printing techniques of Ceramic printing, where we use a water-slid glaze decal to coat a white piece of vitreous enamelled steel with an image. We then spray an additional layer of powdered borosilicate glass (similar to the Gorilla Glass you find on your smartphone screen) to add an additional layer of protection against the elements. This layer is then baked again, to fuse the glaze in with the substrate below, and also to melt the glass to form a vitreous glass layer which covers the image. With this triple-stage protection, where we use an already tough enamel coating with a baked in image, sealed under flexible, scratch and chip resistant glass, we can guarantee an image will be protected against UV Fade and scratch damage for up to 25 years. The average lifespan of a Ceramic image is approximately 15 years, whilst Dye-sublimated aluminium (Also known as “Lifetime Images) will have at most a 5-10 year lifespan.

Wow, that sounds amazing! what’s the catch?

Like with all baked imaging products including Ceramic and Dye-Sublimated aluminium, Vitreous Enamel will not be able to reproduce Magenta, pink and Purple tones all that well. This is primarily because of the fact that Magenta (Hot pink) and red inks are the first to fade when exposed to intense heat.

The best way to see this in action is to look at an old car with red or purple paint. Purple, Red and Magenta are colours which absorb a lot of heat and UV light (and because radiated heat is essentially Infrared light, a considerable amount of IR), and tend to retain it for a long period of time before being able to release that heat, seeing as a car’s clear coat is a good absorber of heat. As such, you tend to see that red, magenta and purple paints fade faster than other colours due to this high energy retention property. This is why you tend to see the clear-coat on red and purple cars deteriorate faster than any other car colour.

Now, in saying that, this does not mean that you’ll see bubbling clear coat like that on an old car. Seeing as the glass coating is a lot stronger than a car’s clear coat, and glass tends to be a good transmitter of heat, unlike most acrylic clear coats, the colours will retain their appearance. However, the fading occurs during the baking process, where the plaque is exposed to temperatures in excess of 2,500 degrees C. This generally does not affect skin tones (Which mostly come out in the brown, orange and yellow spectrum rather than as a pink or red), but it may affect things such as clothing items, flowers, or any background elements that may be important to the image.

This is why when we design a Vitreous Enamel Plaque for you, if we detect a large amount of Pink, Red or Purple in the design, we’ll send you a proof just to make sure that the result is to your satisfaction. If it isn’t, we can either recolour the image to better suit the printing process, or we can discuss alternatives to allow you to use that photo as a part of your design.

Vitreous enamel produces simply stunning results when the image has a lot of brown, orange, yellow, green, blue, and white tones. These colours are much more resistant to intense heat, and therefore will survive the heat transfer process with no major change in appearance.

How much does a vitreous enamel plaque cost?

Well, this is entirely dependent upon the size you request. The best way to get a price on Vitreous Enamel plaques is to contact us directly. You can email your photographs to us, and the design team can give you a proof as to how they will turn out when they go through the printing process.

Leave a Reply

Want to join the discussion?Feel free to contribute!